FEATURES

When selecting the clamp diameter, the dimensions of mating components on which the clamp is to be installed must be accurately established to enable effective clamping. The durometer hardness of the soft material and desired compression are important factors when determining the appropriate clamp diameter.

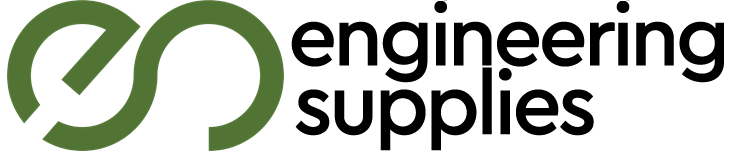

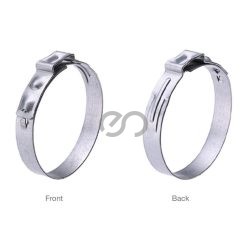

Tensioning tunnels

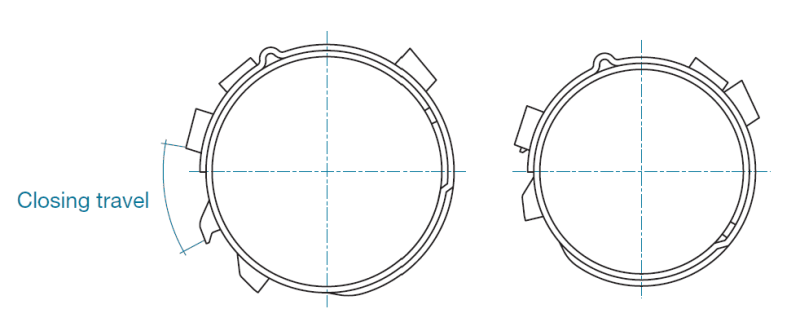

The tensioning tunnels have been developed to withstand a maximum closing force of 2000 N. By using an Oetiker closing tool and applying it at the tensioning tunnels, the clamp is reduced in diameter until the load-retaining hook is located within the tunnel and engages with the leading edge. The diameter reduction of the clamp is proportional to the closing travel, but slightly influenced by elongation of the tolerance-compensation element under high loads. The theoretical maximum reduction in diameter is given by the formula:

Max. diameter reduction = closing travel / π

Tolerance compensation

The tolerance-compensating elements come into effect when the nominal diameter of the closed clamp cannot be achieved due to adjacent components being at the upper levels of the tolerance range. When parts being clamped have high durometer hardness values, the compensating element can be fully elongated providing the closed position is still achievable.

For optimum performance, a clamp diameter should be selected based on the theoretical lower tolerance limits of the components. Then, when the larger dimensional assembly is encountered, the tolerance compensation element is elongated to absorb the increased diameter and allow the load-retaining hook to engage in the tensioning tunnel. The application configuration, the physical properties of the materials being sealed and the required retention, are all critical factors when determining the overall functionality of the connection.