FEATURES

Material Dimension

The StepLess® ear clamps are available in standard widths and thicknesses. The band dimensions must be selected so that they take the required radial forces and the hose characteristics into account and secure the necessary sealing and / or retention properties for the corresponding environmental conditions.

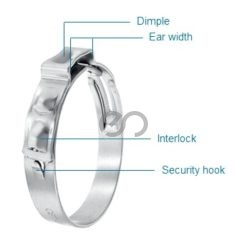

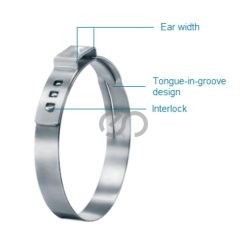

Clamp ear (closing element)

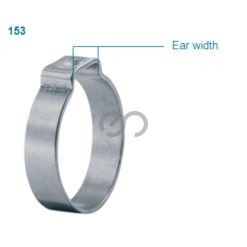

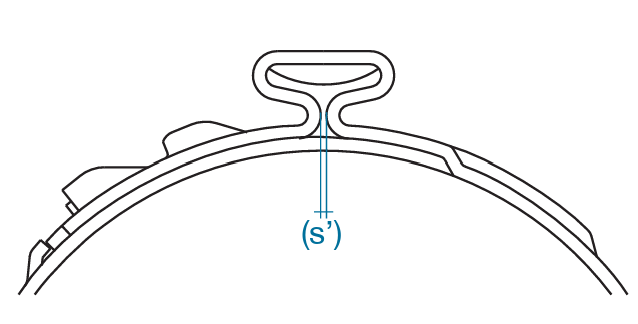

Using tools designed or endorsed by Oetiker, the clamp is closed by drawing together the lower radii of the “ear”. The maximum diameter reduction is proportionate to the open “ear” width (s). The theoretical maximum reduction in diameter is given by the formula:

Max. diameter reduction = Ear width (s) / π

Notice: The above sketch shows the appearance of a closed “ear” (s’); it does not necessarily indicate an effective closed assembly.

The following applies as a guideline: To determine the correct clamp diameter, push the hose onto the attaching material, (e.g. the nipple), and then measure the outer diameter of the hose. Select a clamp whose average value of the diameter range is slightly greater than the hose’s outer diameter. The clamp is only sufficiently closed (minimal diameter reduction) if the original ear width is reduced by at least 40% (for an ear with a 10.7 mm width) or 50% (for an ear with a 13 mm width) and the correct closing force was applied during assembly.

Block Closure

Block closure is when the assembly force fully closes the ear, resulting in both ear legs touching (vertical members between the ear dimple and clamp radius). When this occurs the assembly force is absorbed by compressing the legs rather than transferring the assembly forces to the parts being clamped. If assembly forces are going to be measured, a block closure must be avoided.

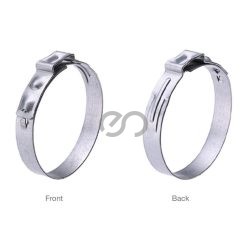

Security Hook

The standard series will be delivered with security hook. Optionally the clamps can be ordered without security hook.