FEATURES

Technology

Oetiker 1-Ear Clamps 251 are featured by the cross welding technology, which is an innovative welding technology, that combines flexible production of various sizes with a highly robust welding seam connection of the stainless steel band ends.

Field of application

Oetiker 1-Ear Clamps 251 are universally applicable. They are especially suitable for Medical, Industrial Equipment, Appliances, Food & Beverage and other industrial applications as well as for vehicle applications like for example Fuel Line and Occupant Safety.

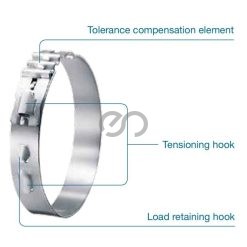

Oetiker 1-Ear Clamps with insert

This type of clamp combines the geometry and properties of the 1-Ear Clamp with an insert made of stainless steel. These clamps are ideal for demanding applications involving soft or hard rubbers and plastics. The thin-walled insert ring (up to 0.3 mm thick), with an oval protrusion that locates in the ear space, bridges the ear gap and ensures almost uniform compression around the whole circumference of a clamp.

Edge condition

The band edges are deburred during the manufacturing process providing reduced risk of damage to parts being clamped.

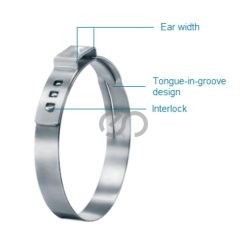

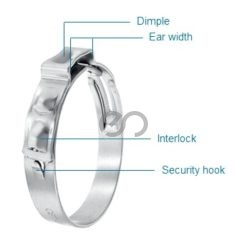

Clamp ear (closing element)

Using tools designed or endorsed by Oetiker, the clamp is closed by drawing together the lower radii of the “ear”. The ear should be closed by at least 40% of the original ear width.

The maximum diameter reduction is proportional to the open “ear” width. The maximum reduction in diameter is given by the formula:

Max. diameter reduction = Ear width (s) / π

Single tool stroke closure only, do not apply secondary crimping force.