All our thread gauges come with TEST Certification accredited by NPL (National Physical Laboratory) or NABL (ISO/IEC 17025) standards laboratories.

PRECISION-DRIVEN INNOVATION

Minimizing gauge downtime is our top priority. We combine rapid turnaround times with unwavering precision to consistently deliver accurate results.

Backed by over 25 years of hands-on experience, our seasoned metrology experts are equipped to tackle even the most demanding calibration challenges

RIGOROUS PROCESSES

RELIABLE COMPLIANCE AND CONFIDENCE

Our comprehensive calibration services cover our entire range of precision gauges, supporting both UKAS-accredited and in-house certification requirements.

Recognizing that regular recalibration is essential to maintaining accuracy, we ensure your tools perform flawlessly—every time.

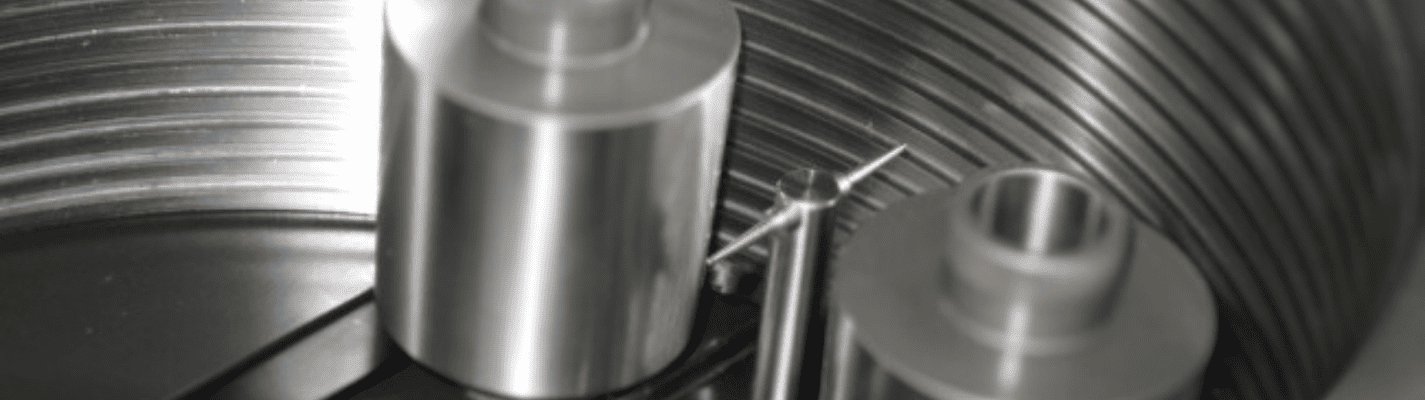

STATE-OF-THE-ART MEASUREMENT TECHNOLOGY

We’ve invested significantly in advanced CNC metrology and optical calibration equipment, surpassing traditional manual methods. This cutting-edge technology enhances our calibration accuracy and enables us to deliver reliable, repeatable results you can trust.

100% TESTING

Every gauge we produce—whether thread, plug, ring, or custom types—is carefully tested to ensure it meets strict dimensional, material, and functional standards before packaging and dispatch. We also offer third-party calibration services to provide an added layer of assurance for accuracy and reliability – AT EXTRA COST

Continuous Improvement Process

At our company, quality control is not a one-time action — it’s a continuous journey. We follow a structured Continuous Improvement Process (CIP) to consistently enhance the performance, precision, and reliability of our gauges.