FEATURES

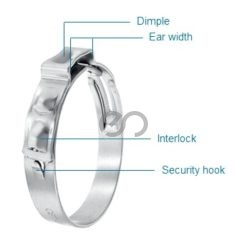

Technology

Multi Crimp Rings 250 are featured by the cross welding technology which is an innovative welding technology, that combines flexible production of various sizes, including large diameters, with a highly robust welding seam connection of the stainless steel band ends.

Field of application

The Multi Crimp Rings 250 are universally applicable due to their large diameter range. They are especially suitable for cooling and heating systems, for Air Intake Systems and further applications which require strong and low profile sealing.

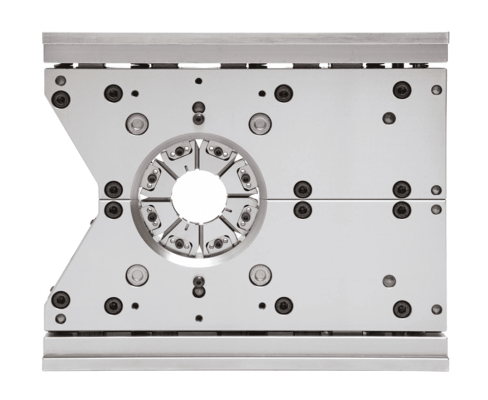

Material dimensions

Oetiker Multi Crimp Rings 250 are available in various band dimensions. To ensure the required sealing and/or retention performance the band dimensions and compression rate needs to be chosen properly. The nature of the hose or boot as well as the environmental conditions like mechanical or thermal stress need to be taken into account to guarantee a reliable connection. Oetiker Engineering offers consulting and testing service to find the best solution for your application.

Diameter reduction

The maximum possible diameter reduction is dependent on the nominal diameter and band-thickness of the Multi Crimp Rings 250 as well as on the swaging tool used. The nominal diameter of the Multi Crimp Rings 250 should be kept as close as possible to the diameter of the parts being clamped in order to shorten shrinking times, simplify positioning, and reduce the material load on the MCR. Oetiker Engineering offers support to select the correct diameter for your individual application.