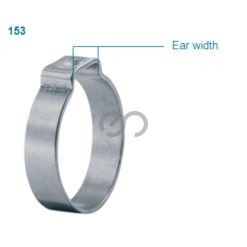

FEATURES

Oetiker ER Clamps are made from a single, standard strip dimension. The clamp diameter must be determined very accurately to ensure correct operation in service – the required radial force, the nature of the hose and the necessary sealing and retaining properties are all extremely important.

Particular attention must be paid to the compressibility and wall- thickness of the material being joined. For assistance, please contact Oetiker.

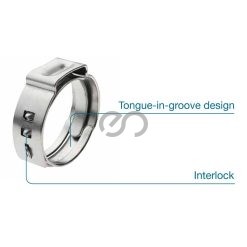

Load retaining hook

Closure is achieved when the load retaining hook engages in the load retaining window. Both hook and window have been specially developed for this type of clamp. The reduction in diameter of the Clamp ER is proportional to the closing travel, which is approx. 4 mm. The maximum diameter reduction is thus given by the following formula:

Max. diameter reduction = closing travel π

The very thin material, from which these clamps are made, only 0.25 mm, means that after assembly there is only a very small step where the two ends of the clamp overlap. The effect of this is that the ER Clamps exert almost uniform compression, or surface pressure, on clamped parts.

The result is effective clamping of compressible materials for all manner of applications. The sealing characteristics of Clamps ER depend on the resilience provided by the compressed elastic material of the parts joined.